For for this tile design, in the ceramic studio I experimented by using my knowledge of rapid prototyping and CAD modeling in Rhino, to realize forms with a tessellating geometry.

This was opportunity to test a fairly realistic production method, starting from the 3D CAD development which was compiled to CAM and cut with CNC router into foam board, to make mold core. With that a 2 piece plaster mold was made to pour liquid ceramic, to form a tile in about 3 minutes.

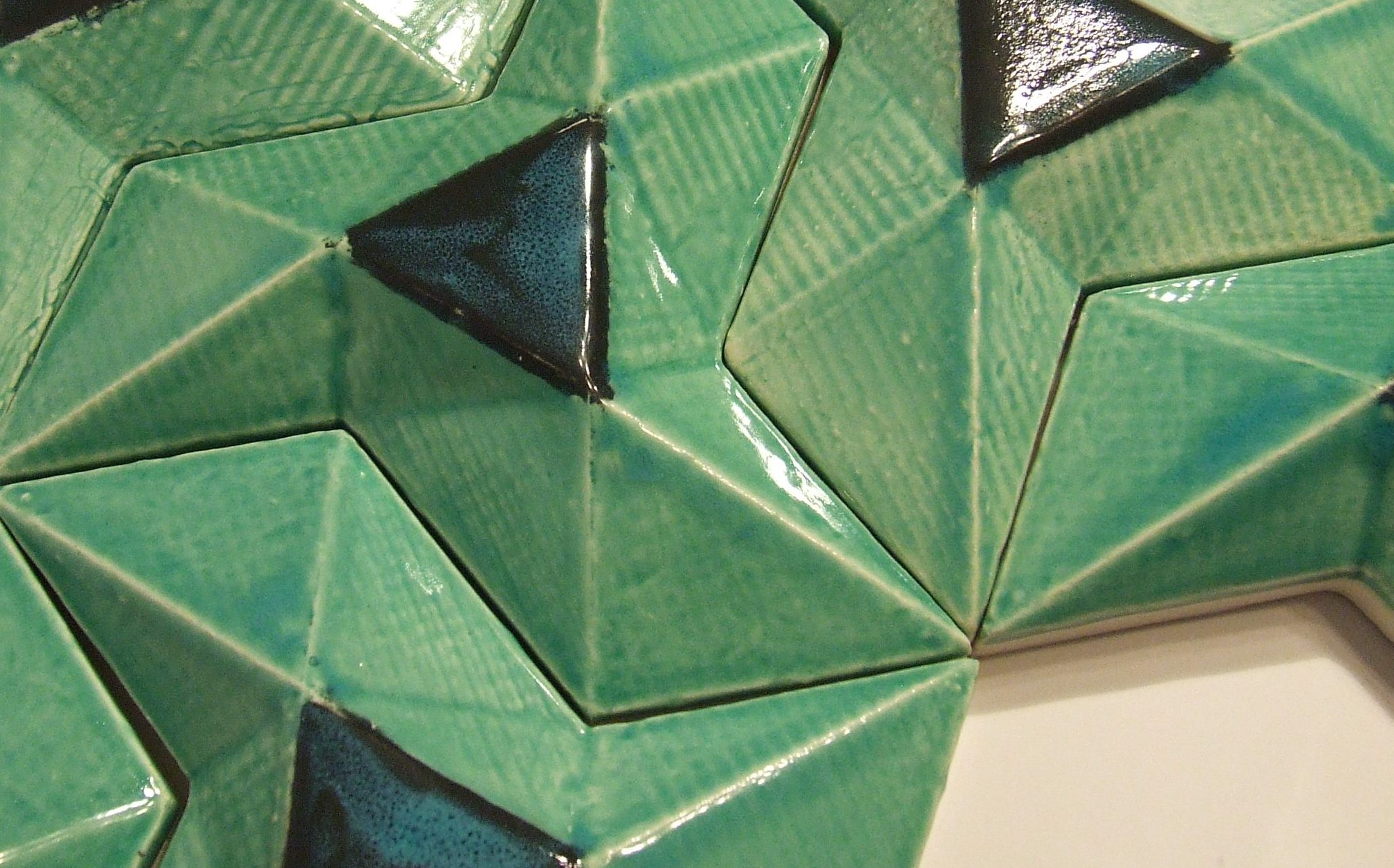

I also didn’t want to process the cut foam shape too much as the cutting tool left its own path creating a direction in every tile, and I felt it was an interesting texture to leave for the mold to preserve that would introduce different details in the final finish. It would vary depending on the colour and other properties of the glaze chosen for fire the tile in the Kiln, you can see some of the green colour variation and the so-called grain.

Rhino 5, CNC foam plug, slip cast clay cone 6

You must be logged in to post a comment.